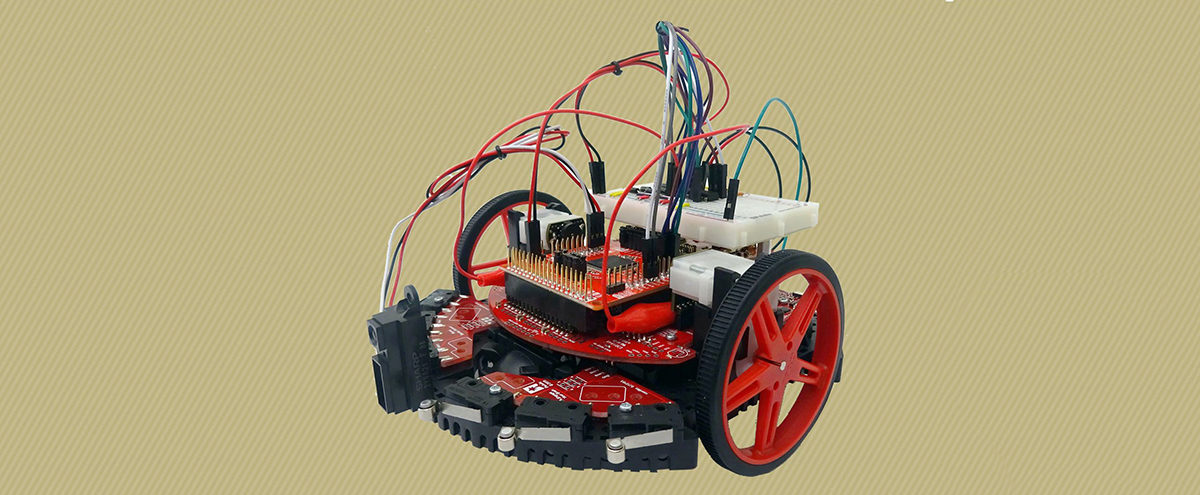

Without Ever Stepping Foot on the Tech Campus. The remote-controlled obstacle avoiding robot, pictured here, was built by students in Prof. Jon Rogers' MOOC. Barely a pound in weight, the tiny 6"-by-6" vehicle had to be able to detect obstacles around it and automatically avoid bumping into the ones in its path. Students built motor driver circuits that regulated its speed and learned to program the development board that allowed it to sense obstacles using an analog distance sensor and six bump switches. The robot was controlled by receiving remote commands through a PC/laptop via serial communication protocol.

Without Ever Stepping Foot on the Tech Campus. The remote-controlled obstacle avoiding robot, pictured here, was built by students in Prof. Jon Rogers' MOOC. Barely a pound in weight, the tiny 6"-by-6" vehicle had to be able to detect obstacles around it and automatically avoid bumping into the ones in its path. Students built motor driver circuits that regulated its speed and learned to program the development board that allowed it to sense obstacles using an analog distance sensor and six bump switches. The robot was controlled by receiving remote commands through a PC/laptop via serial communication protocol.

|

| Dr. Jonathan Rogers Lockheed Martin Associate Professor of Avionics Integration |

Scooters that rent themselves and bill your credit card company.

Refrigerators that know when to deliver ice.

Dryers that stop when the clothes are dry.

Over the last 20 years, the number of consumer devices and machines that routinely use microcontrollers, sensors, and actuators to deliver goods and provide services has exploded. If a device isn’t smart, it’s often considered obsolete. Driving this trend is mechatronics – a hybrid engineering discipline that encompasses mechanical engineering, electrical engineering, robotics ….

And Jon Rogers.

The Aerospace Engineering professor recently launched a new online course, Mechatronics Revolution: Fundamentals and Core Concepts that likewise exploded. Within two months, more than 8,000 students from 149 countries had enrolled in the Massively Open Online Course (MOOC). Students continue to enroll at a fast pace and Rogers is now working on a follow-up MOOC on control systems implementation.

Like other MOOCs, it’s free (unless you want to be graded and receive a certificate) and it has a more relaxed pace than on-campus courses (you have access to lectures for up to a year). But Rogers doesn’t think that these things are driving enrollment.

“First of all, mechatronics skills are highly marketable, in every corner of the world. If you have them, you are immediately very employable,” he said. “And in this course, students have the option of buying a lab kit to build a fully functioning robot on their own. That’s the best way to learn basic mechatronics, but I don’t think there’s another MOOC out there that offers this hands-on mechatronics experience. Our students learn the fundamentals of mechatronics by building a system, making mistakes, and spending whatever time it takes to track down the bugs.”

|

| Siavash Farzan Aerospace Engineering Doctoral Student |

Engineering Education Online

Coordinated by EdX, a nonprofit educational platform that facilitates MOOCs for more than 140 universities, Rogers’ class delivers basic concepts, terminology, and discipline knowledge to students via a series of video-taped lectures that can be viewed at any time. If they want to earn the certificate upon completion of the coursework, students pay fees for the lab kit and to have their work evaluated by Rogers and the doctoral student who helped design the lab, Siavash Farzan.

The material covered is introductory, as far as mechatronics go. Rogers teaches some fundamentals of embedded C++ programing and focuses on open-loop design as well as simple closed-loop systems such as finite state machines.

“The next step from here is more advanced closed loop system implementation, where feedback is used in more advanced control algorithms,“ he said. “That’s a class for students who are comfortable with advanced math. We’re working on that MOOC now.”

Rogers depends on the lectures to give students a familiarity with the material before they take on the labwork.

“By the time they go to the lab assignments, they’ve already heard me using the terms a few times. They’ve seen me explain the diagrams. And they’ve probably even seen me holding some of the components in my hand. When it’s their turn to physically put the integrated circuit on the circuit boards or connect up the motors, that’s when they cement their knowledge. That’s when they know they can join the mechatronics revolution.”

Engineering the Revolution

Rogers was more skeptical than intrigued two years ago when reps from Texas Instruments first floated the idea of a lab-based online mechatronics class. A lot would have to change if this was going to work.

“The idea of grading someone’s construction of a robot without ever seeing it was difficult to grasp,” he said. “There are no other lab-based MOOCs out there to compare this to, so I didn’t know if it would work.”

Before taking the challenge, Rogers sought the advice of Wayne Whiteman, an academic professional and online course developer in the School of Mechanical Engineering. Whiteman told Rogers straight-up that the numerous MOOCs he’d designed were some of the most rewarding work of his life.

“And then I started to think about the goals I have that are not defined by my job. I passionately believe that higher education should be available to anyone who wants to learn, regardless of his or her socio-economic background or ability to pay tuition. There’s a lot of reasons why smart, driven people cannot make it to the Georgia Tech campus to learn about mechatronics and this MOOC will would give them a chance.”

Engineering the Solutions

Rogers teamed up with Farzan to tackle each of the curriculum hurdles like a classic engineering problem.

First of all there was the equipment issue. There could be no presumption that students would have access to any of the specialized fabrication or testing machines that are readily available on campus. No voltmeters, oscilloscopes, or soldering irons.

“So we had to adjust our thinking on materials,” he noted. “We built the robots using hardware that is typically used for prototyping. It doesn’t result in a particularly robust system – you have to solder for that. This will not survive a lot of use. But it does teach the students how to put a robot together, which is the point of the labs.”

Another concern was lab directions. The mechatronics course taught on campus has labs with three or four pages of instructions – enough to lead students without directing them. For the MOOC students, Rogers and Farzan produced a 10-page manual that covered every imaginable mistake, trouble-shooting technique, and debugging process.

“The students in this course can get some help in the online mechatronics forum, which is monitored by Siavash. And some of them actually use this to help each other, which is great,” said Rogers. “But we know the MOOC students do not have access to office hours or other resources, so we wrote these manuals to try to minimize their need for assistance as much as possible.”

Probably the biggest hurdle Rogers and Farzan faced was grading, where the functionality of each lab assignment has to be evaluated without ever being seen. For this, they borrowed some techniques from their colleagues in the College of Computing.

Each student is given a piece of code that they must embed in the software for each lab. When the devices in each lab are ready for grading, the embedded code records their performance and outputs text files that go directly to Vocarium, a website that is built for online grading.

“Within a matter of minutes, Vocarium is able to deliver results for up to 1,000 assignments,” said Rogers. “And the grade pops out from edX.”

Interested in taking this course? Enroll now.