Rapid Prototyping. Emory University physician Jay Sanford and his wife Joanne are seen testing the intubation cover that Sanford and Aerospace Engineering doctoral student Lee Whitchter refined over the last week. Using volunteers from the newly created community group, ABC, Sanford and Whitcher will now set up a distributed manufacturing network to fabricate the PPEs for widespread use by the medical community.

|

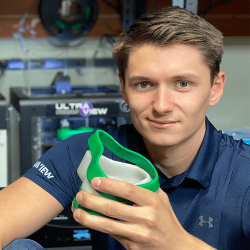

| Lee Whitcher |

The same COVID-19 virus that has emptied the streets of Atlanta has transformed aerospace engineering doctoral student Lee Whitcher into a PPE designer, a non-profit foundation founder, and a community organizer.

All in about two weeks.

"When this all hit, and we moved to remote instruction, I realized it was a great opportunity to focus on my dissertation uninterrupted," he said. "I set myself up in the dining room, where my better half, Kirstin, a school teacher, was also working. But I couldn't shake the feeling that I have a particular set of skills and experience that could make a real difference in the fight against Covid-19."

Whitcher was not alone.

Engineers from GTRI and the Georgia Tech's School of Mechanical Engineering immediately stepped up to design and manufacture face shields that have been supplementing the dwindling supplies available to Atlanta area hospitals. Whitcher contributed to that effort, but felt there was more he and others could do.

Within 24 hours of realizing his dissertation could wait, Whitcher had reached out to more than 600 colleagues, fellow maker space geeks, and AE alums to form ABC - Atlanta Beats COVID, an all-volunteer non-profit that has been organizing Atlanta-area maker spaces to design and fabricate protective personal equipment (PPE) for healthcare providers, first responders, and other essential personnel.

Teamwork at its Best |

When the first round of Wisconsin Face Shields were ready for delivery, volunteers from the Maker Station in Marietta, transported them to the Atlanta Metro Ambulance Service. They were greeted by some very happy EMTs (above). Georgia Tech alumnus  Kolby Hanley runs UltraView, a company that makes archery parts, but when he got the call from ABC, he donated his time, expertise, and equipment to help Whitcher fine-tune his design for an easily manufactured respiration mask. Kolby Hanley runs UltraView, a company that makes archery parts, but when he got the call from ABC, he donated his time, expertise, and equipment to help Whitcher fine-tune his design for an easily manufactured respiration mask.Read more about their collaboration  By day, Shelley Wunder-Smith is the senior writer/editor at Georgia Tech's ISyE School. But, since the COVID 19 crisis, she has been volunteering as the communications director for Sewing Masks for Area Hospitals - Atlanta, one of the many groups involved in the ABC coalition. By day, Shelley Wunder-Smith is the senior writer/editor at Georgia Tech's ISyE School. But, since the COVID 19 crisis, she has been volunteering as the communications director for Sewing Masks for Area Hospitals - Atlanta, one of the many groups involved in the ABC coalition. The Aerospace Engineering School depends on Kelsey Gulledge to manage our social media, but during her off-hours, she has been moonlighting for Sewing Masks for Area Hospitals-Atlanta: sewing masks, of course, but also running the group's social media. The Aerospace Engineering School depends on Kelsey Gulledge to manage our social media, but during her off-hours, she has been moonlighting for Sewing Masks for Area Hospitals-Atlanta: sewing masks, of course, but also running the group's social media. Hanif Hoseini, a post-doc in the School of Aerospace Engineering, has been at-the-ready for ABC, helping to manufacture the group's first shipment of Wisconsin Face Shields. He is seen here modeling one of those shields at the Maker Station. Hanif Hoseini, a post-doc in the School of Aerospace Engineering, has been at-the-ready for ABC, helping to manufacture the group's first shipment of Wisconsin Face Shields. He is seen here modeling one of those shields at the Maker Station. Mechanical specialist Greg Rogerson, of the AE School's Machine Shop, used the water jet to fabricate parts for the ventilator initiative that was spearheaded by the School of Mechanical Engineering. He was often accompanied by his colleague, Scott Moseley (not pictured.) |

A day later, ABC had raised $5,000 and was on its way to organizing volunteers to design and/or manufacture respirator masks, face shields, soft sewn masks, surgical gowns, and ventilators. Almost immediately his collaboration with Georgia Tech alumnus Kolby Hanley led to the development of a 3D-print a respirator casting kit that non-engineers will soon be able to use to manufacture the masks wherever they are needed.

"The minute this began, we started getting requests for not just a few, but hundreds of pieces of personal protective gear," said Irmgard Diorio, executive director of Decatur Makers, one of several area maker spaces in ABC's network.

"But also, from the beginning, we listened to Lee's vision, which was to produce equipment that first-responders need. Sanitation and social distancing are key, but ABC is also reviewing designs to make sure they will ultimately be used by the medical community."

As the original 60 volunteers ballooned to more than 200, Whitcher organized ABC into several working groups to tackle the burgeoning logistics of crisis engineering: equipment sanitation, transportation, software development, sewn face shields, manufacturing issues, volunteer recruitment, and design reviews. Armed with a cellphone at all times, he has remained in contact with all of them, but is particularly focused on the manufacturing arm.

On April 1, that effort produced its first results: 200 "Wisconsin Face Shields" were delivered by ABC volunteers to Atlanta Metro Ambulance Service. The mask is so called because the design originated at the University of Wisconsin Maker Space, which shared it to expedite their manufacture. The "open source" culture that prevails in the maker space community has been a boon for ABC's mission.

"We have hundreds of people in Atlanta who have 3D-printers in their homes and are downloading designs to help out," Whitcher said. "Of course, we began in the Decatur Makers, but we've also been working with the Sewing Mask for Area Hospitals-Atlanta, GeekSpace Gwinnett, Roswell FireLabs, and Marietta Maker Station. There is a growing community of technical and creative thinkers volunteering their talents. It's really quite amazing."

Also amazing is the fact that Whitcher himself has found time to employ his engineering skill to design new, easily manufactured PPE's for quick distribution. His first two projects - an N-95 grade respirator that can be sanitized and reused, and an intubation cover that will protect medical personnel from effluvial splatter when intubating a COVID-19 patient - are in production.

Emory University physician Jay Sanford has been working with Whitcher to create the intubation cover-- a lightweight, polycarbonate enclosure originally devised by a physician in the Philippines. While the two refine

this equipment, Whitcher has been designing a distributed manufacturing network that will ultimately allow volunteers to fabricate hundreds of covers in their homes, using simple tools and directions.

And then there's Georgia Tech, where Whitcher has been working with the AE Machine Shop as they print and manufacture parts to be used in the manufacture of 20 ventilators -- part of the larger effort spear-headed by colleagues in Tech's School of Mechanical Engineering.

"I have slept maybe four hours a night, and my house is a disaster. It's not just me. All of us involved in ABC and at Georgia Tech are mortified by the danger that this virus has put on medical providers and first-responders. We are doing what we can to fight back," Whitcher said of his whirlwind introduction to community organizing.

William R. T. Oakes School Chair Mark Costello commended him for putting his education to the test.

"When people ask me how engineers approach huge over-arching systems problems, well, Lee is modeling it. Whether it's building a CubeSat that will orbit the Moon or organizing the community to fight COVID-19. You gather all relevant information surrounding the problem, tap into the best resources to build a solution, and then get to work. That's what engineers do."

If you have a story to tell us about how you have fought back at, been taught a lesson by, or outsmarted COVID 19, drop us a line at communications@ae.gatech.edu. We are here to tell your story.

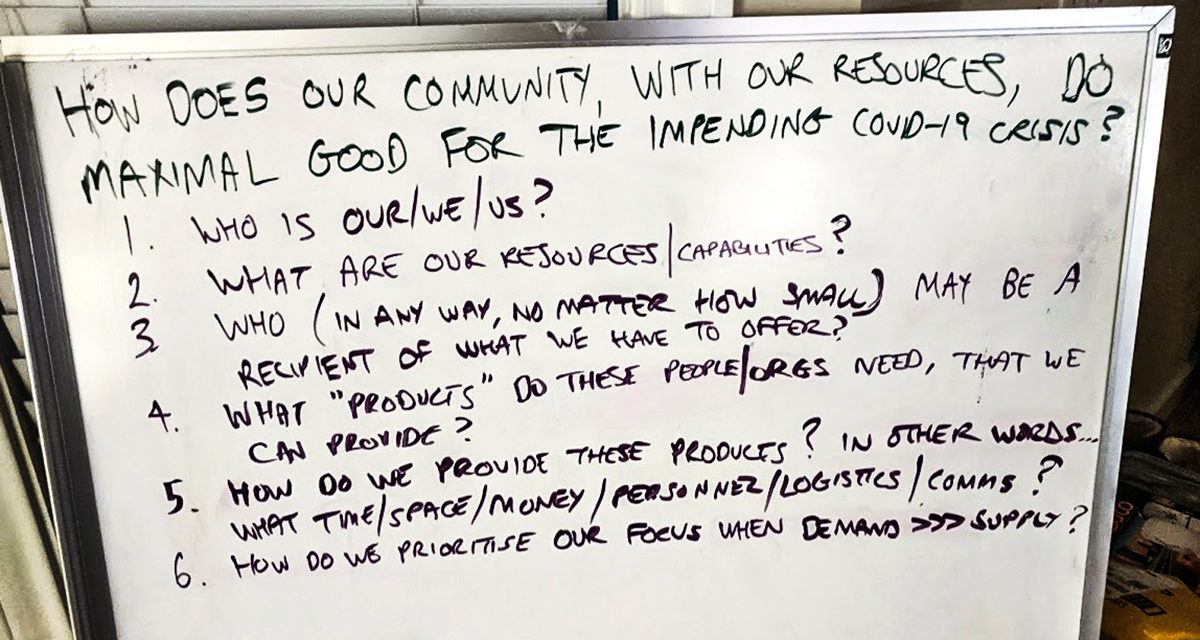

As any engineer will tell you: it all starts with a white board. This chicken scratch on a white board in Whitcher's home was the beginning of what became ABC.