|

| Ready to Hot-Fire. With more than 80 members from multiple GT Schools, the Yellow Jacket Space Program is ready to take on the future of space flight. Seen here are members of the YJSP Propulsion Team, from left, Mackinnon Poulson (AE), Patrick Palmetshofer (AE), Benjamin Zabback (ME), Trenton Charlson (AE), Amalique Acuna (AE), and Jim Richards (ATDC mentor) standing at the launch site in Douglas County last month. Not shown: Samuel Kim (ECE), and Kyle Lundberg (AE). Check out the video |

The Yellow Jacket Space Program (YJSP) got one step closer to realizing its ultimate mission last month, when its seven-student Propulsion Team hosted two successful static hot-fire tests of its YJ-1S engine at a privately owned test site in Douglas County.

|

| This is what 750 pounds of thrust looks like. |

A registered student organization, the YJSP 's ultimate goal is to design and launch a suborbital rocket past the Karman line (100 kilometers) - a feat that will allow students and other researchers in Atlanta to test new technology and perform experiments in space.

The hot-fire tests on November 21 and November 24 were the first-ever firings of a student-developed liquid rocket engine, said AE doctoral student Johnie Sublett, YJSP's president. The tests allowed the team to assess the engine’s thrust, chamber pressure, and overall performance on the ground and gather the necessary data needed to develop a version for flight. The testing also exposed YJSP members to a massive design and hands-on skill building experience - two things that are rare outside the commercial spaceflight industry.

"This test represents the culmination of just over two years of concentrated effort by our propulsion team and is the first 100% student-designed, student-built, and student-tested liquid rocket engine produced by Georgia Tech," said fourth-year AE student, Trenton Charlson, the lead engineer on the YJ-1S engine.

|

| This is what teamwork looks like. From left, Kyle Lundburg, Patrick Palmetshofer, Amalique Acuna, and Sam Kim working on the engine controller just before the test began. |

“It’s one thing to learn fluid dynamics in the classroom, but actually building a system that delivers over 1.5 kilograms per second of kerosene and liquid oxygen into a combustion chamber at precisely the pressure and flowrate you want is a completely different animal. We went through nearly a dozen iterations of our feed system design and hand bent and flared hundreds of tubes to produce our plumbing. It’s thrilling to see our hard work designing, fabricating, testing, and troubleshooting our systems pay off in this test.”

Building an engine that could produce 750 pounds of thrust was no easy feat. The majority of the components for the YJ-1S had to be designed and manufactured by the YJSP members, who spent countless hours in the AE School's Machine Shop getting the job done. The team also had to become experts on the fundamentals of working with cryogenic propellants at high pressure.

“We did quite a bit of system testing with liquid nitrogen before moving on to liquid oxygen for our static fire test," said Charlson. "Success with liquid nitrogen proved that all our components could withstand temperatures below minus 300 degrees Fahrenheit. We discovered quite a few areas for improvement, and the team is already working on the next iterations of the design which will be capable of longer burn times and better overall performance.”

|

|

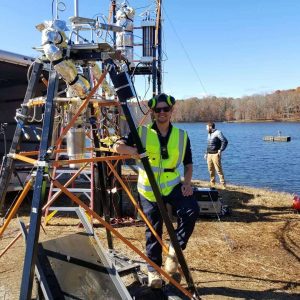

Prior to Fire. Lead engineer Trenton Charlson stands by his engine. |

In January of this year, the group launched TIAT - a small (10kg) high-performance solid rocket-fuel vehicle that tested the systems that provide active stability assistance during flight. Looking ahead, the team seeks to improve the YJ-1S engine and implement regenerative cooling, along with integrating it into a flight vehicle.

For now, however, the successful hot-fire test is enough to make this a very happy holiday season.

"It's exciting because this test showcases the drive of Georgia Tech students, who have spent thousands of man-hours developing a system that will safely and successfully deal with the numerous complexities of launching a rocket," said Sublett.

Inaugurated in 2015, the Yellow Jacket Space Program is supported by Georgia Tech's Student Government Association (SGA), Georgia Tech's ATDC, and numerous industry sponsors, including Brennan Industries, Gems Sensors, Material, Prentex Alloy Fabricators, Marotta Controls, Blue Origin, Boeing, Creavy Seal, LORD Sensing, Turbines Inc., Lockheed Martin, American Seal & Engineering, Avco Valves, Braddock Metallurgical, and Omega.